A Guide to the Application of CORTEX

Laser Scanning and Diffraction Gauges

General:

The DG (Scanning Laser Gauge) and WG (Laser Wire Gauge) type instruments

manufactured by CORTEX Research and

Development Ltd. can measure the outside diameter of cylindrical objects,

such as rods, tubes, cables, wires or fibres. The measurement is fast (up to

200 measurements/sec), precise and contact-free. The diameter range spanned by

these instruments is from 10 micrometer to 50 mm.

Both instrument

types (DG and WG gauges) are similar in that they basically consist of a Measuring Head and an industrial PC

based Control Unit with a keypad and

colour LCD monitor. One control unit can handle one or two measuring heads,

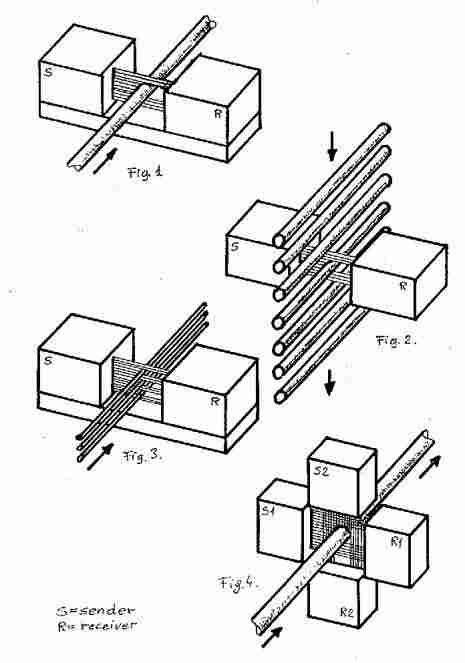

depending on the application. The layout of these heads is similar in that there

is a sender and a receiver part, and the object to be measured is placed

between them (Fig. 1).

Measuring principles:

The WG Laser Wire Gauges have a stationary

laser beam. The object to be measured is placed into the laser beam and diffracts (scatters) the light beam.

The diffraction pattern is detected in the receiver head via a one dimensional CCD light sensor, digitised and

evaluated by the control unit to obtain the diameter of the object. This principle is

especially suited for objects of small diameter, such as wires or fibres.

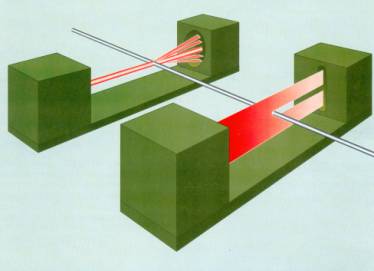

The sender part

of the DG Scanning Laser Gauges

produces a scanning (up-down moving)

laser beam (vertical line) and the object to be measured is placed into this

beam and its „shadow” is detected at the receiver part. This principle is used

for measuring larger diameter objects.

Application of the WG1C Laser

Wire Gauge :

The typical

application of the WG Laser Wire Gauges is the measurement of very thin

objects, such as copper, tungsten and molybdenum wires. The typical diameter

ranges are 10 - 500 m but diameters up to 1 mm

(optionally 2 mm) can be measured.

The basic

function of these instruments is to measure and display the wire diameter and to

classify it according to programmed parameters (typically nominal diameter and

tolerances). This can be extended with several options, such as SPC (Statistical Process Control)

evaluation, analogue outputs (e.g. for chart recorder or process control),

interfacing to a drawing or spooling machine to qualify a given length (spool)

of wire either during manufacture or at the Quality Control of the finished

product.

Normally one

measuring head is connected to a control unit, however if required two measuring heads can also be

connected. This makes the following applications possible (depending on the

software of the control unit):

·

Two independent diameter measurements at approximately the same location

(cost effective solution).

·

Measurement of the same wire at two different manufacturing stages (e.g. copper wire

without and with lacquer layer).

·

Measurement of the same wire in two orthogonal directions to obtain ovality data.

Application of the DG Scanning

Diameter Gauges

The application

of the DG Scanning Diameter Gauges are very widespread.

Basically two

types of gauges are available: The DG1C

Gauge performs precise measurements with 0.1 m resolution and works in the 0,05 -

10 mm measuring range (20 mm on special request), while the DG50C Gauge has a resolution of 1 m and a 1 ‑ 50 mm

measuring range.

The main

application of the DG1C Gauge is the QC of

wires and cables or small machined parts during or after the manufacturing

stage.

The DG50C Gauge can be used for similar

measuring purposes for diameters up to 50 mm in harsh industrial environments.

All the options

mentioned before (analogue outputs, double measuring heads, interfaces etc.)

can be applied in the case of the Scanning Diameter Gauges as well.

Some of the

most frequent applications are:

·

Continuos diameter measurement of copper, tungsten and molybdenum wires

during and after manufacture

·

Measurement of cables

·

Measurement of plastic rods and tubes

Application of Diameter Gauges

in glass tube manufacture

The DG50C

device has found wide spread use in the glass

industry for measuring glass tube. A special characteristic of CORTEX equipment is that a reference signal is inputted from the glass

cutter, which enables the gauge to classify and

sort (usually via solid state relays) the

cut-up glass tubes while the measurement is performed on the continuos tube

on the drawing line, before the cut is made.

A further

option is a 4-20 mA Proportional and/or

PID control signal output for process control.

Thus one diameter gauge placed on the drawing line can provide the

following functions, usually performed by several gauges:

·

Measure and display of the continuos

tube diameter

·

Classification and sorting of the

cut up glass tubes according to several tolerance classes

·

PID process

control signal (for air-blow or drawing speed regulation)

·

Data collection (standalone or

by monitoring PC via serial line).

The measuring

systems can be expanded with the following measuring options:

·

Laser measuring system for sensing glass

imperfections (knots and stones) in glass tubes

·

Vision system for measuring the bow

(curvature) of cut up glass tubes

·

Measurement of wall thickness

of glass tubes

Special Applications of the DG Scanning

Diameter Gauges

Below we list

some of the special applications developed so far for the diameter gauges:

·

Measurement of cut up glass tubes for compact

fluorescent lighting sources (CFL). In this special application only one

head is used, but the glass tubes travel parallel to the laser scan direction

and also rotate. Thus as the tube traverses the measuring range, its diameter

is measured at different angles of rotation, which enables to sort the piece according

to both the diameter and ovality into different tolerance classes (Fig. 2).

This system can be extended with the measurement of tube-end tilt and tube length to provide complete QC of the product.

·

Measurement of several wires

with one gauge (Fig. 3).

·

X-Y head

arrangement for the measurement of ovality of wires (DG1C), glass tubes and hot

rolled iron rods (DG50C) (Fig. 4).

·

Measurement and control of steel

rods on the grinding machine. In this application the grinding machine step

motor is directly steered with programmable parameters by the control unit

according to the difference between the measured and nominal diameter.

Data Collection

Option:

All diameter measuring instruments

can be supplied as an option in a special version for data acquisition. The functions of the software

typically include SPC data acquisition,

display and data logging according to work shifts and tube types. Alternatively

several WG and/or DG devices can be linked to an overhead

monitoring-evaluation system (PC) by the standard serial interface (RS232

or RS485) or via local computer network (Ethernet) for similar data collection

purposes. Special software for a given application can be developed on request.

Figures: